Exploring the Use of Recycled Materials in Cement Production

26.05.2025

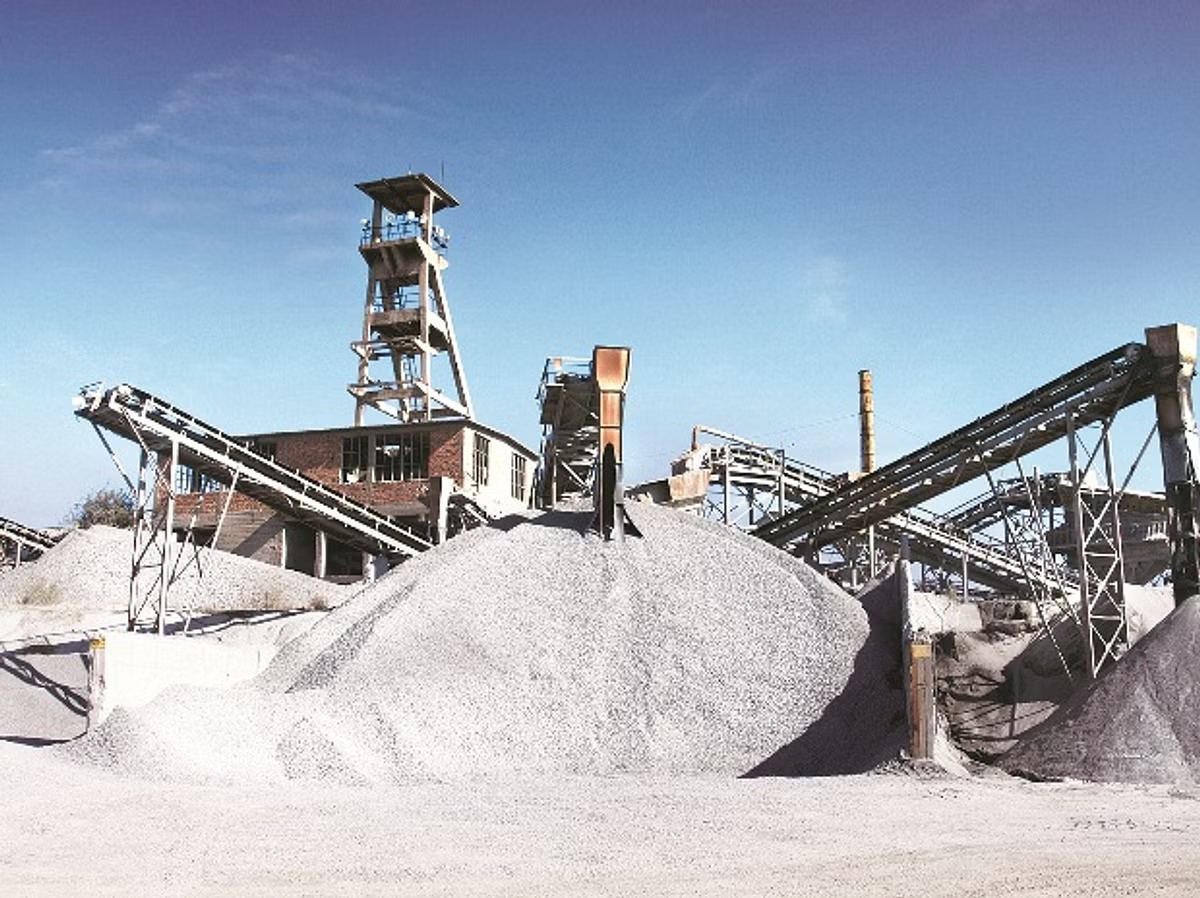

The global construction industry is under increasing pressure to reduce its environmental impact. Cement production, being a major contributor to carbon emissions, is now embracing innovative methods to become more sustainable. One such approach involves the use of recycled materials in the cement manufacturing process.

This article explores how integrating recycled materials can benefit the cement industry, the types of materials commonly used, challenges faced, and the future outlook for this sustainable shift.

Why the Cement Industry Is Turning to Recycled Materials

Cement production accounts for approximately 7–8% of global CO2 emissions. The demand for more sustainable practices has led researchers and manufacturers to explore alternative inputs. Recycled materials offer a promising solution to reduce both emissions and the depletion of natural resources.

By using waste products as supplementary materials, cement plants can reduce their carbon footprint, decrease landfill waste, and lower production costs. This move aligns with the growing trend of circular economy principles in construction and industrial manufacturing.

Common Recycled Materials Used in Cement Production

1. Fly Ash

Fly ash is a by-product of coal combustion in power plants and is one of the most widely used recycled materials in cement. It enhances the workability and durability of concrete and reduces the need for clinker, the most carbon-intensive component of cement.

2. Slag

Ground Granulated Blast Furnace Slag (GGBFS), a by-product of steel manufacturing, is used to produce high-performance cement. It offers improved resistance to chemical attack and enhances the long-term strength of concrete mixtures.

3. Silica Fume

Silica fume is collected from silicon metal or ferrosilicon alloy production. When added to cement, it increases compressive strength and reduces permeability, making it ideal for high-strength concrete applications.

4. Recycled Concrete Aggregate (RCA)

Old concrete that is crushed and reused as an aggregate in new mixes helps conserve natural stone resources. RCA is widely used in road construction and non-structural applications, contributing to material reuse on construction sites.

5. Waste Glass

Finely ground waste glass acts as a pozzolanic material when added to cement. It helps reduce alkali-silica reactivity and enhances the aesthetic appeal of finished concrete with a polished appearance.

6. Construction and Demolition Waste

Crushed bricks, tiles, and other construction waste can be processed and reused in cement blends. While quality control remains a challenge, ongoing research is making these materials increasingly viable.

7. Recycled Gypsum

Gypsum, used in the final stage of cement production to control setting time, can also be sourced from recycled drywall and plasterboard waste. This reduces mining and disposal needs.

Environmental and Economic Benefits

Utilizing recycled materials in cement production brings multiple environmental benefits. Primarily, it reduces greenhouse gas emissions by lowering clinker content. It also minimizes the exploitation of virgin raw materials such as limestone and clay.

Economically, manufacturers can benefit from reduced energy consumption and raw material costs. Some recycled inputs, such as industrial by-products, are readily available and less expensive than traditional components.

Challenges in Implementation

Despite its benefits, integrating recycled materials into cement production is not without challenges. The variability in quality and composition of recycled materials can affect the performance of the final product. Consistent sourcing and testing are crucial to ensure safety and reliability.

Another challenge is regulatory compliance. Construction standards vary by country and may restrict the use of certain materials in structural applications. Public perception and industry conservatism also play a role in slowing down adoption.

Technological Innovations Supporting the Shift

Advancements in material characterization and concrete technology are helping to overcome barriers. Machine learning and AI-driven quality control systems can predict and adjust mix performance when recycled materials are introduced.

Thermal treatment and chemical activation methods are also being developed to improve the reactivity of recycled materials, making them more compatible with cement formulations.

Real-World Applications and Case Studies

Many countries have already embraced recycled materials in cement. In the Netherlands, fly ash and slag-based cements are widely used in infrastructure projects. Japan has pioneered the use of recycled aggregate concrete in public buildings.

Companies like LafargeHolcim and HeidelbergCement have launched eco-friendly cement products that incorporate significant portions of industrial by-products, showcasing the commercial viability of sustainable cement production.

The Future of Recycled Materials in Cement

The cement industry is on a clear path toward greener production methods. As climate regulations tighten and demand for sustainable construction grows, the use of recycled materials will become more mainstream. Research and government incentives will be key drivers in this transition.

Collaboration among construction firms, waste processors, and cement producers is essential for scaling up the use of recycled inputs. With the right infrastructure, standards, and innovation, recycled materials could become a cornerstone of the cement industry’s sustainability strategy.

Conclusion

The integration of recycled materials into cement production is no longer just a theoretical idea—it’s a practical, necessary step toward sustainability. By rethinking raw material sourcing and embracing innovation, the cement industry can significantly reduce its environmental impact while maintaining high product standards.

As awareness grows and technology advances, recycled materials will play a vital role in shaping the future of cement production, helping to build a more responsible and resilient construction sector.