The Role of Cement in Reducing Structural Defects

30.09.2025

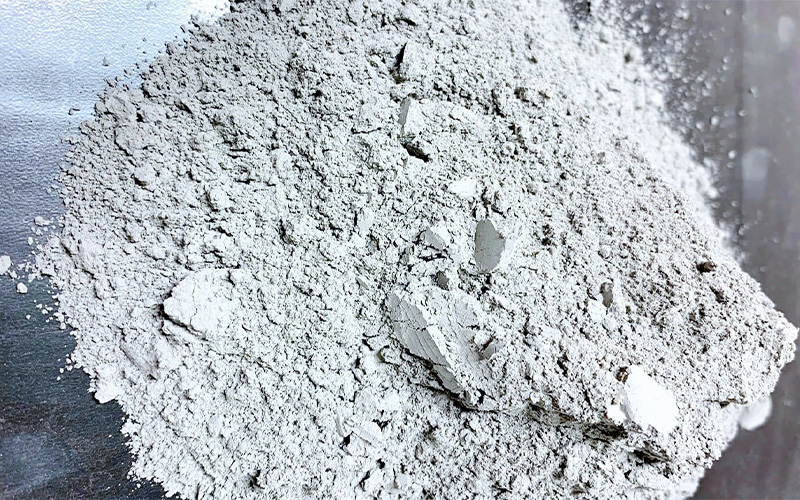

Introduction: Cement as the Foundation of Durability

Cement is more than just a binding material—it is the foundation of structural integrity in modern construction. When used properly, high-quality cement helps minimize structural defects such as cracks, shrinkage, and durability failures. Reducing these defects is vital for ensuring safety, longevity, and cost-effectiveness in residential, commercial, and infrastructure projects.

Common Structural Defects in Construction

Structural defects can arise from poor material quality, improper design, or inadequate construction practices. Common issues include:

- Cracks: Caused by shrinkage, thermal expansion, or overloading.

- Weak Bonding: Poor adhesion between aggregates and cement paste.

- Durability Failures: Structures exposed to weathering or chemicals degrade over time.

- Corrosion of Reinforcement: Due to permeable or low-quality concrete mixes.

Each of these problems can be mitigated through the correct choice, handling, and application of cement.

How Cement Reduces Structural Defects

1. Enhanced Compressive Strength

High-quality cement improves the load-bearing capacity of structures. This strength prevents early cracking and deformation, ensuring long-term stability under heavy usage.

2. Controlled Setting Times

Cement with balanced setting properties allows proper finishing and placement. This reduces shrinkage cracks and improves structural bonding during curing.

3. Reduced Permeability

Properly mixed cement reduces water penetration, which in turn prevents corrosion of reinforcement steel. Low permeability also minimizes freeze-thaw damage and chemical attack.

4. Compatibility with Admixtures

Certified cement works effectively with admixtures such as plasticizers, waterproofing agents, or retarders. These combinations enhance durability, reduce shrinkage, and improve workability, minimizing defects during and after construction.

5. Improved Bonding with Aggregates

Strong adhesion between cement paste and aggregates enhances overall concrete strength. Better bonding reduces micro-cracks and increases resistance to stress and vibrations.

6. Specialized Cement Types

Using the right type of cement for specific environments lowers the risk of defects. For example, sulfate-resistant cement prevents deterioration in coastal areas, while low-heat cement reduces thermal cracking in massive pours.

Best Practices for Using Cement Effectively

- Quality Testing: Ensure cement meets ISO, ASTM, or local certification standards before use.

- Proper Mix Ratios: Use correct cement-to-water and cement-to-aggregate ratios for intended applications.

- Curing Techniques: Maintain optimal moisture and temperature to reduce shrinkage and surface cracking.

- Skilled Labor: Train workers in handling and application methods to prevent workmanship-related defects.

Case Studies

1. High-Rise Buildings

High-strength cement mixes reduced shrinkage cracks in skyscraper projects, ensuring both safety and aesthetic quality over decades.

2. Coastal Infrastructure

Use of sulfate-resistant cement prevented corrosion and cracking in seawater-exposed bridges and harbors, extending service life.

3. Public Roads and Pavements

Optimized cement ratios in pavement concrete reduced joint cracking, improving durability under heavy traffic loads.

Challenges and Considerations

While cement plays a critical role in reducing defects, challenges include:

- Cost Pressure: Temptation to use low-grade cement to cut expenses.

- Improper Storage: Cement exposed to moisture loses strength, increasing risk of defects.

- Lack of Quality Control: Inconsistent mixes on-site lead to uneven strength and durability.

Future Outlook

Innovations in cement are further reducing structural defects:

- Self-Healing Cement: Microcapsules or bacteria-based additives repair cracks automatically.

- Smart Cement: Embedded sensors detect stress and prevent early-stage failures.

- Green Cement: Eco-friendly formulations combine sustainability with durability for defect-free structures.

Conclusion

Cement plays a central role in minimizing structural defects, ensuring that projects are safe, durable, and sustainable. From enhanced strength to specialized formulations, the right use of cement prevents common issues like cracks, shrinkage, and corrosion. By adopting quality standards, proper handling, and innovative cement technologies, construction teams can deliver defect-free structures that stand the test of time.